PEX pipe installations have become increasingly popular across residential and commercial projects in the UAE. Thanks to their flexibility, durability and ease of installation, PEX systems offer a modern alternative to traditional metal piping. Though the advantages of having the best water pipes are numerous, incorrect installation can result in diminished performance and even lead to issues for the homeowner. As a reputable water pipe distributor in the UAE, Quantum Industries is of the opinion that understanding the most frequent issues experienced during installation of water pipes is one of the most beneficial steps in creating reliable, long-lasting and efficient plumbing systems for your home.

PEX pipes are known for being adaptable, corrosion-resistant and suitable for both hot and cold water applications. But like any material, they must be handled correctly. Whether you are a contractor, installer or property owner, avoiding these mistakes can help ensure that your plumbing system performs exactly the way it should.

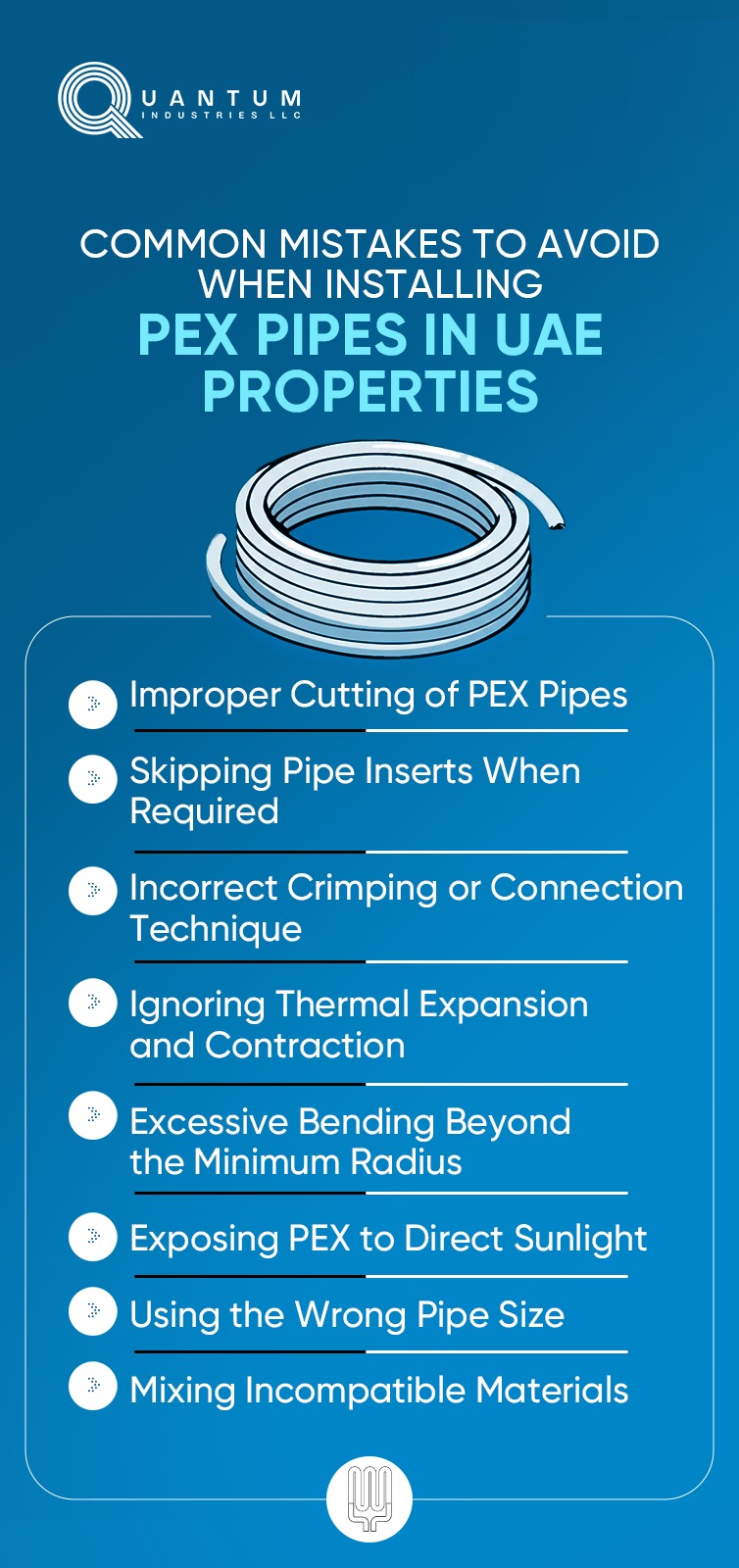

One of the most basic yet frequently overlooked steps is cutting the pipe properly. PEX pipes need a clean, even cut to ensure a tight seal with fittings. Using a standard knife or worn-out cutting tool can create uneven edges, which may lead to leaks over time.

Always use a proper PEX pipe cutter. It ensures a straight and smooth cut, giving your fittings the best chance of creating a secure and watertight connection.

Many compression-style PEX fittings require internal pipe inserts or stiffeners to maintain shape. These small components prevent the pipe from collapsing when tightened. Skipping this step weakens the connection and eventually leads to leaks.

Always check the fitting type you are using. If inserts are required, make sure they are fully seated before tightening the connection.

PEX systems use different connection methods, such as crimp, clamp or expansion fittings. Each requires the correct tool and proper technique. Under-crimping or over-crimping are both common issues. An under-crimped connection can leak, while an over-crimped one may damage the pipe or fitting.

Installers should always verify crimps using a go/no-go gauge and ensure that tools are properly calibrated. For expansion systems, the pipe must be allowed to fully retract around the fitting before pressurising the system.

PEX expands and contracts significantly with temperature changes. In a climate like the UAE, hot water pipes may undergo frequent thermal shifts. If the installation does not account for this movement, it can lead to stress on joints, pipe deformation or even pulling the pipe out of supports.

Allow for natural movement by incorporating expansion loops, offsets or flexible routing. Never clamp the pipe rigidly without space for thermal movement.

PEX pipes can bend, but only to a certain extent. Every pipe size has a minimum bend radius, and forcing the pipe tighter than recommended can cause kinks. Having a pipe that has an angle is not good for water flow; this causes the pipe to be weak and can create a failure point.

A designated elbow fitting should be installed in place of the kinked pipe if there is a need for a sharp turn in the water line. It's best to do your layout before installing your system to reduce unnecessary bends in the pipe.

PEX can degrade under prolonged UV exposure. In the UAE, where sunlight is intense throughout the year, this is especially important. Leaving PEX pipes exposed to direct sunlight during storage, transport or installation can weaken the material long before it goes into service.

PEX should always be kept stored in a shaded area. If a PEX pipe must be installed on something outdoors or through an area that is not protected from sunlight, it should be insulated with some type of insulated tubing or pipe cover made specifically for UV protection.

7. Inadequate or Skipped Pressure Testing Before Transfer of ResponsibilityMany PEX installers will skip or rush through pressure testing because they feel it takes too long. A system that appears secure might still have minor leaks that only reveal themselves under pressure. Once walls are closed or tiles are installed, fixing these issues becomes much more complicated and expensive.

Always conduct a proper pressure test before completing the installation. Hold the test for the recommended duration and ensure there are no drops in pressure.

Using incorrect pipe sizes can result in poor water pressure, inconsistent flows or unnecessary material waste. Undersized pipes create bottlenecks, while oversized ones may complicate layout and increase costs.

Following manufacturer sizing charts and calculating flow requirements based on the number of fixtures helps ensure an efficient and effective plumbing system.

PEX systems may be very flexible in their usage; however, not every type of fitting or material in a PEX system is compatible to each other and using random or mismatched types of fittings and/or materials could lead to severe damage or issues such as corrosion, leaks or differing rates of expansion under temperature changes. Even though the initial connections may hold up nicely, they could fail at some point early on.

To avoid compatibility issues, use fittings and connectors specifically approved for use with PEX. By installing your PEX with a professional, you ensure that your PEX systems will perform as intended over time with a reduced risk of sudden breakdowns.

The Importance of Professional Installation

Although installing PEX is relatively straightforward, when you hire an experienced installer, they will maximize performance and provide a safe installation. An experienced installer has the knowledge necessary to correctly assess pressure ratings, expansion factors, load factors, and connection methods. They also have access to specialised tools and testing equipment that guarantee accuracy and safety.

Choosing reliable manufacturers and suppliers makes a significant difference as well. When installation is done properly, PEX piping systems provide a wide variety of advantages to properties located in the UAE. For the best possible installation of PEX piping in the UAE, it is necessary to select the highest quality PEX pipe and provide professional installation support to help installers create the most efficient PEX piping system.

Avoiding common mistakes such as improper cutting, poor support, skipping inserts or ignoring thermal movement can dramatically improve reliability and extend the lifespan of the plumbing system. With careful attention to installation standards and the right materials, PEX pipes can deliver years of trouble-free service.

Quantum Industries continues to support the region with high-performance PEX solutions backed by technical expertise and dependable customer assistance. As one of the leading Pex pipe manufacturers in Dubai, we remain committed to delivering quality, reliability and long-term value to every project.