HVAC systems are not just about heating and cooling anymore; they are now more about being efficient, durable, and reliable on a long-term basis than ever before. Pipes are the backbone of how well an HVAC system will function over time. Quantum Industries is a reliable supplier of piping products and HVAC pipeS and fitting manufacturer in UAE.

Quantum Industries Manufacturing has developed new products and systems through the use of advanced material technologies designed to improve the durability and applicability of HVAC piping systems. An example of innovation is the introduction of multi-layer fibre technology to improve the performance and longevity of HVAC piping systems in a variety of residential, commercial and industrial projects.

HVAC systems operate under demanding conditions. They are exposed to constant temperature changes, internal pressure, mechanical stress, and long operating hours. Conventional piping materials have difficulty keeping their expected performance for extended durations due to their inability to adapt to the extreme climate conditions of an area such as the UAE.

The advantages of multi-layer fibre technology are that they provide structural support, long-lasting thermal stability, and flexibility in various environmental conditions. In this blog, let’s explore more about How Multi Layer Fiber Technology Enhances HVAC Pipes Reliability.

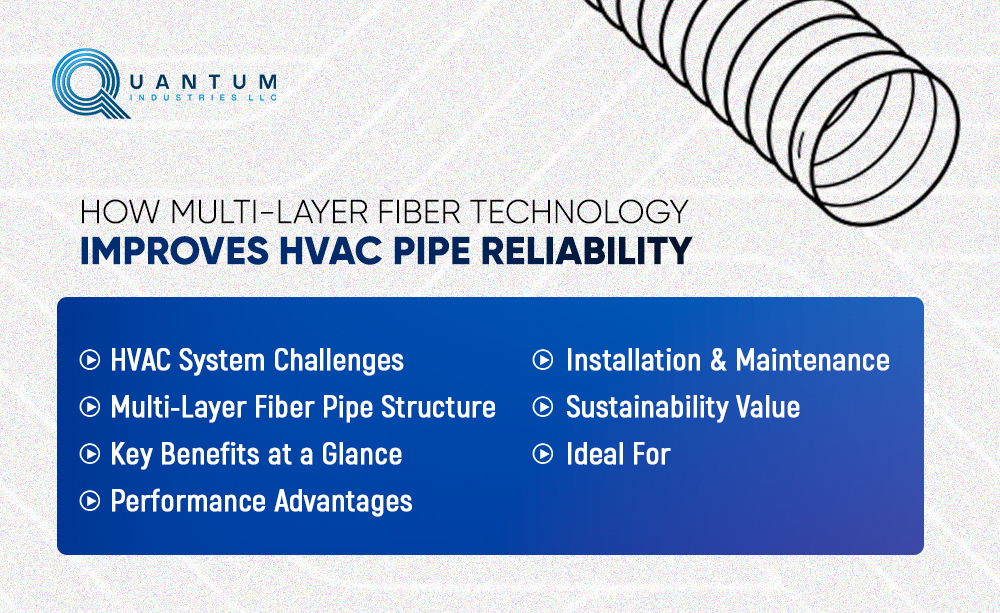

Multi-layer fiber technology means combining multiple material layers into a single pipe structure. Each layer serves a specific function, working together to improve overall performance. The pipe layers typically consist of an inner layer that transports the liquid or gas, a fibre-reinforced intermediate layer that provides support to the other layers of material and an outer layer that provides strength and resistance to environmental damage.

The fibre-reinforced layer is the most critical component of this type of piping, as it provides enhanced mechanical strength with only a small increase in weight compared with a single-type pipe, allowing for greater pressure, thermal and mechanical load capacity than equivalent single-type pipes.

Multi-Layer Fiber HVAC Pipes provide improved strength relative to single-layer pipes, which is critical because HVAC systems typically require their pipes to be able to withstand the momentary loading from changing internal temperatures and the constant cycling of water through the pipe due to HVAC circulation. The fiber reinforcement helps disperse the load evenly throughout the pipe wall, thereby helping to eliminate failures resulting from cracks, local deformities, and catastrophic breaks.

This enhanced strength ensures that pipes maintain their shape and integrity even under high operational demands. For large buildings, where HVAC systems run continuously, this reliability is essential to prevent downtime and costly repairs.

Thermal performance is a critical factor in HVAC piping. Pipes must handle both chilled and moderately heated water without excessive expansion or contraction. Thermal expansion and contraction are minimized with the use of multi-layer fiber technology. This results in less stress on joints, fittings and support structures which helps to limit the occurrence of leaks and provides a more stable installation.

Consequently, the longevity of the service life of the HVAC system is greatly increased when combined with other benefits of using multi-layer fiber technology in an HVAC application where temperature varies from high to low.

Over time, repetitive stress caused by temperature changes and pressure cycles can weaken pipes. Single-layer materials are more prone to fatigue-related damage. Multi layer fiber pipes, however, are designed to absorb and distribute stress across multiple layers.

The fiber reinforcement acts as a stabilising core, minimising micro-cracks that may develop internally. This resistance to fatigue makes these pipes particularly suitable for large HVAC networks where long-term reliability is non-negotiable.

Despite their enhanced strength, multi layer fiber HVAC pipes remain lightweight compared to traditional metal piping. This balance of strength and reduced weight makes transportation, handling, and installation easier.

Lightweight pipes reduce labour effort during installation and place less load on building structures. This is especially beneficial in high-rise buildings and large commercial projects where system weight must be carefully managed.

HVAC systems often generate noise and vibration during operation. Pipes that transmit these vibrations can contribute to discomfort within buildings. Multi layer fiber pipes help dampen vibration and reduce noise transmission through the system.

The layered construction absorbs operational vibrations more effectively than rigid materials. This results in quieter HVAC operation, enhancing indoor comfort in residential complexes, hotels, offices, and healthcare facilities.

HVAC pipes are constantly exposed to treated water, chemicals, and sometimes condensation. Corrosion can significantly shorten the lifespan of metal pipes, while certain plastics may degrade over time. Multi layer fiber pipes are engineered to resist corrosion and chemical reactions.

The inner layer is designed to handle fluid flow without reacting with water or additives, while the outer layer protects against environmental exposure. This resistance ensures consistent performance and reduces maintenance requirements throughout the system’s life cycle.

In large HVAC installations, system consistency is critical. Variations in pipe quality can result in uneven flow, pressure drops, or temperature inconsistencies. Multi layer fiber pipes offer uniform internal surfaces and stable dimensions, promoting smooth fluid flow throughout the network.

This consistency helps HVAC systems operate at optimal efficiency, reducing energy consumption and improving temperature control across different zones of a building.

Another key advantage of multi layer fiber technology is improved joint reliability. Reduced thermal movement and structural stability ensure that fittings and joints remain secure over time. This minimises the likelihood of leaks at connection points, one of the most common issues in HVAC systems.

Stable joints not only improve system reliability but also reduce the need for frequent inspections and repairs, saving time and operational costs.

Durability directly contributes to sustainability. Pipes that last longer reduce material waste, replacement needs, and resource consumption. Multi layer fiber HVAC pipes support sustainable building practices by offering extended service life and reduced maintenance demands.

Additionally, efficient HVAC systems contribute to lower energy consumption, aligning with modern sustainability goals and green building standards.

As buildings become more complex and performance expectations increase, the materials used in HVAC systems must evolve. Multi layer fiber technology represents a shift toward smarter, more resilient piping solutions that address both current and future demands.

For developers, consultants, and facility managers, choosing advanced piping systems means fewer disruptions, lower life-cycle costs, and greater confidence in system performance.

Multi layer fiber technology has transformed the reliability of HVAC piping systems by combining strength, flexibility, thermal stability, and durability into a single solution. By reducing stress, resisting fatigue, and maintaining consistent performance, these pipes support long-lasting and efficient HVAC operations across diverse building types.

Quantum Industries continues to focus on advanced piping technologies that meet the region’s demanding conditions. As a trusted pipe supplier in UAE and a reliable HVAC Pipes and Fittings Manufacturer in UAE, the company remains committed to delivering innovative solutions that enhance system reliability, performance, and long-term value.