Plumbing systems in the UAE face one of the most demanding climates in the world. Temperatures often rise above 45°C, while humidity, saline groundwater, and intense UV radiation continuously stress infrastructure. These environmental factors do not just influence comfort or water use—they directly affect the lifespan and reliability of the pipes themselves.

Continue reading the guide to gain a better understanding of why pipe materials must be carefully chosen and engineered for local conditions by the experts at Quantum Industries, the top pipe supplier in the UAE.

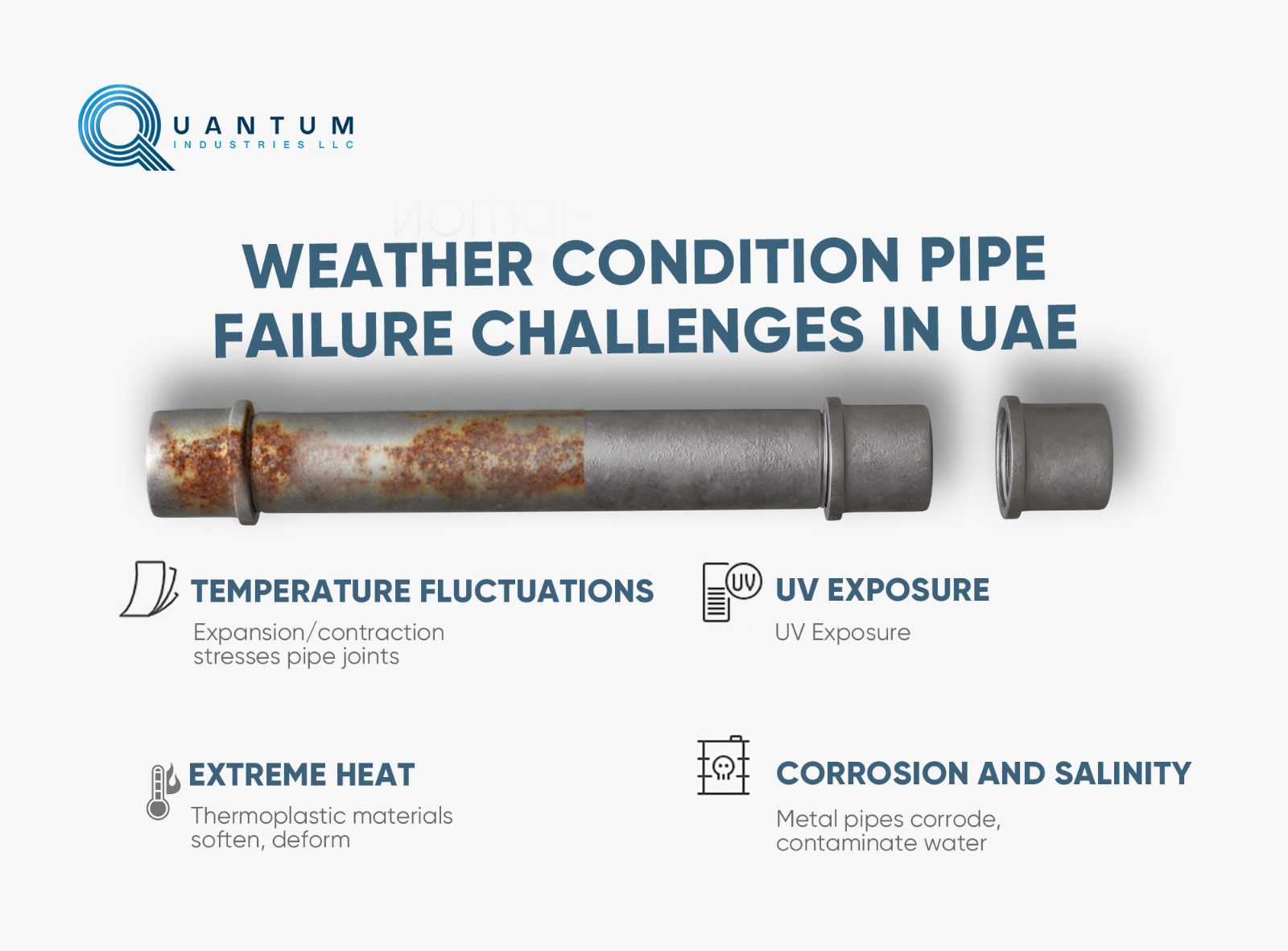

High ambient and surface temperatures cause most thermoplastic materials to expand, soften, or deform over time. Conventional plastic pipes may lose pressure resistance or show signs of creep when exposed to such heat. In rooftop and external installations, the temperature inside pipes can rise far beyond the air temperature, especially when the water supply is stagnant during midday hours.

Qtherm’s PP-R and PP-RCT systems are designed with this in mind. These materials maintain structural stability even at 95°C operating conditions and can handle short-term peaks up to 110°C. Their high molecular structure resists softening, reducing the risk of leaks or joint failures. This thermal endurance makes them well-suited for domestic hot water, HVAC, and industrial fluid systems exposed to the UAE’s intense heat.

Although daytime heat dominates most of the year, UAE nights can bring sharp drops in temperature, especially in desert regions. Such fluctuations create expansion and contraction cycles that stress pipe joints and fittings. Over time, this thermal movement may lead to microcracks, joint misalignment, or water hammer effects when systems restart.

Qtherm’s pipes address this issue through controlled linear expansion properties. The inclusion of glass fiber reinforcement significantly lowers expansion rates compared to standard PP-R. The glass fiber also reduces elongation under thermal load and keeps pipe alignment stable, even when exposed to repeated hot and cold cycles. This minimizes the need for frequent expansion loops or corrective maintenance, making installations cleaner and longer-lasting.

Many regions in the UAE draw water from sources with varying salinity levels, especially in coastal areas where groundwater and desalinated water mix. Traditional metal pipes and fittings are prone to corrosion and scale formation when exposed to saline or chemically treated water. This not only reduces flow but also contaminates the water supply with metallic residues.

Qtherm’s polymer-based systems eliminate this risk. The PP-R and PP-RCT materials are chemically inert and resistant to corrosion from salts, minerals, and disinfectants. Unlike copper or galvanized steel, they maintain clean internal surfaces throughout their service life. This ensures steady flow, consistent pressure, and better water quality—key requirements for both residential and commercial buildings in the Gulf region.

The UAE’s intense sunlight is another major factor that weakens conventional pipes. Prolonged exposure to ultraviolet radiation causes material degradation, leading to surface cracking, color fading, and brittleness. Once UV damage begins, pipes lose mechanical strength and may fracture under pressure.

Q-Therm offers pipes that come with a pre-jacketed UV layer over the pipe’s surface. This thin layer of UV jacket acts as a shield for the pipe against any UV radiation. This UV protection layer is easily peelable from the pipe with a normal knife, without using any sophisticated or dedicated tool.

PP-R and PP-RCT are part of a new generation of thermoplastic materials that combine flexibility with high thermal and mechanical strength. PP-RCT, in particular, uses a modified crystal structure that improves long-term pressure resistance at elevated temperatures. The PP-RCT maintains superior performance under continuous high-pressure conditions, extending the expected service life of hot water systems well beyond conventional standards.

This molecular advantage also means less material fatigue over time. Even when systems operate continuously under UAE’s extreme climate, PP-RCT’s resistance to stress cracking ensures dependable performance for decades.

The high temperature difference between indoor and outdoor environments increases the need for proper insulation of both hot and cold water lines. Without it, heat loss in domestic systems or condensation in chilled water systems can reduce efficiency.

Insulation is provided as a protective measure for above-ground pipe systems against loss of heat or cooling. Qtherm products offer a significantly higher degree of insulation performance due to their low thermal conductivity of 0.20 W/(mK).

Generic imported pipes often fail to meet the challenges posed by the UAE’s unique climate. Materials designed for mild or temperate regions cannot withstand continuous exposure to high UV levels, saline environments, and extreme heat. Using them in local projects can lead to higher maintenance costs, shorter service life, and water quality concerns.

Qtherm’s product range, developed with these local stressors in mind, provides a solution engineered for the Gulf’s harsh conditions. The combination of heat-resistant polymers, UV-stable outer layers, and corrosion-proof construction gives its systems a clear advantage over conventional alternatives. Our focus on testing and compliance ensures that every component—from pipes to fittings and fusion tools—performs reliably in the region’s climate.

This focus on local climatic engineering is what sets Qtherm apart from generic importers and ensures long-term reliability in real operating conditions.

The UAE’s weather is not just hot. It is relentlessly demanding on materials that form the backbone of essential infrastructure. Plumbing systems face constant thermal stress, UV exposure, and water chemistry challenges that can degrade ordinary materials quickly.

Qtherm’s advanced PP-R and PP-RCT piping systems provide an answer built around local realities. Their resistance to heat, pressure, and corrosion, combined with UV protection and low thermal expansion, ensures dependable performance even under extreme conditions. For builders, contractors, and facility managers, this means systems that last longer, require less maintenance, and deliver consistent performance year after year—an outcome that only comes from materials designed with the UAE environment in mind.

Quantum’s Qtherm range is engineered specifically for the UAE’s demanding conditions.

Get in touch with our team to explore durable, thermally stable, and corrosion-resistant piping solutions for your next project.