Understanding the sounds and silence in drainage systems isn’t just about keeping everything running smoothly for facility managers, property owners, and contractors; it’s about avoiding costly problems that can disturb tenants, disrupt operations, and hurt your profits.

The old-style metal drainage systems, like galvanized steel and cast iron, were reliable in their time. But over the years, wear, corrosion, and the water they carry take their toll. At first, these issues show up as small, easy-to-miss signs. Ignoring them, though, can lead to bigger, expensive troubles.

This guide goes beyond simple fixes. It provides a clear way to read what your building’s drainage system is telling you, understand the problems beneath the surface, and consider modern, lasting solutions like choosing the right and reliable pipe supplier in UAE that not only fixes issues but also improves your building’s plumbing for many years to come.

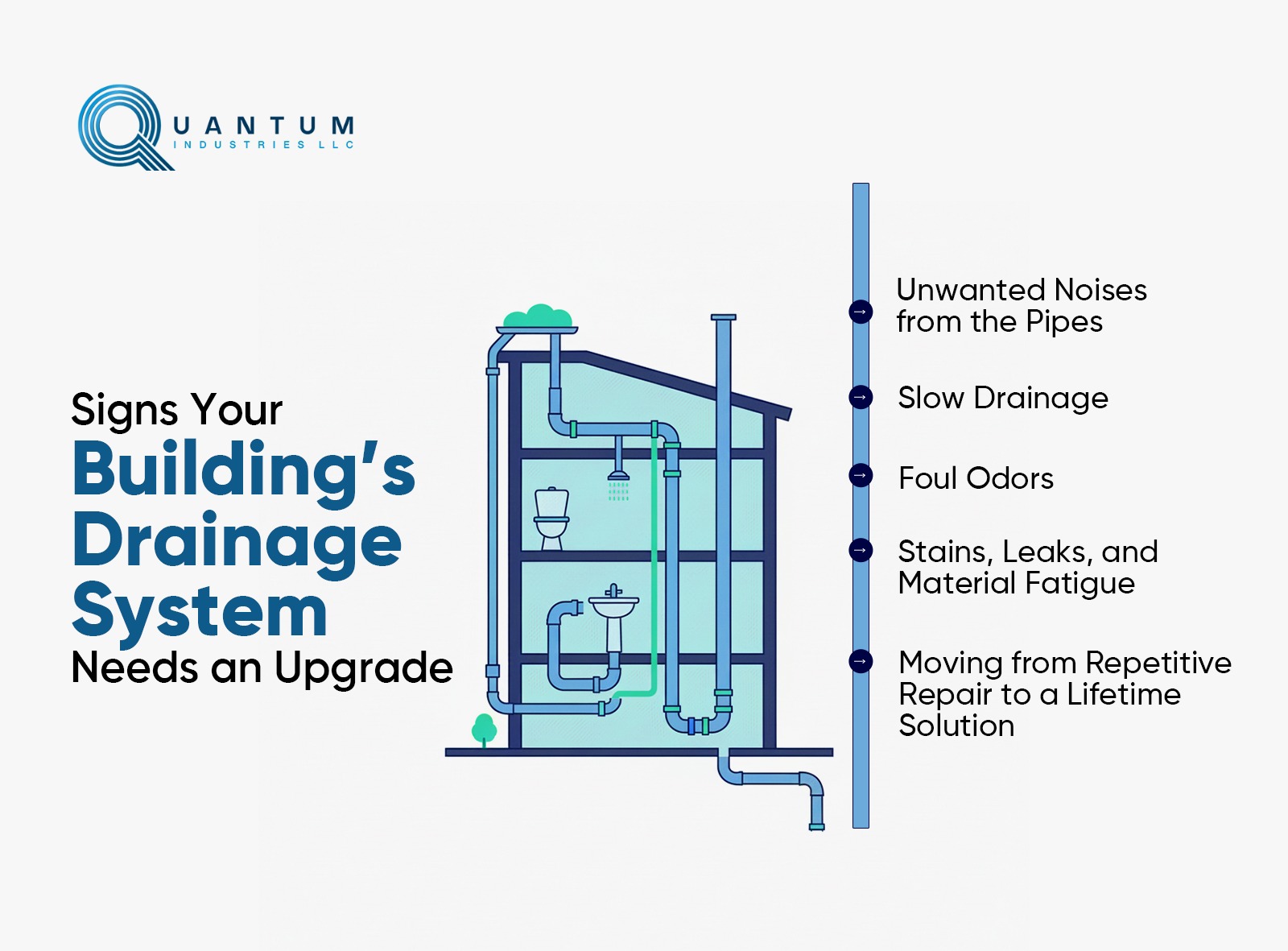

A good drainage system should work quietly and smoothly, showing its health through silence. When it starts making loud gurgles, rattles, and banging noises, it’s sending out signals that something is wrong inside.

These noises show the pipes are wearing out. Rust, mineral buildup, and bubbles make the pipes rub, create pressure issues, and cause vibrations that the whole system has to handle.

Slow drainage is a common sign there's a problem, but people often misunderstand what's causing it. It’s not always just one clog; sometimes, it’s a bigger issue in the system.

The inside of the pipe isn't working well anymore. What used to be a smooth path for water has turned into a rough, narrow tunnel. This causes buildup and makes it harder for water to flow, losing energy and slowing everything down.

Stinky drains are a clear sign that something's wrong. It's important for your health, safety, and happiness as a tenant.

A rotten egg smell (hydrogen sulfide) usually means sewer gas is leaking into the building. This often happens when a P-trap dries out, like in a floor drain or unused sink where water hasn’t flowed in a while, causing the trap to evaporate. But if the traps are full and the smell still lingers, it might mean there's a crack in the vent stack or a damaged seal in the main drain, letting gases escape into the building. In advanced stages of corrosion, the breakdown of the metal itself can produce a distinct, unpleasant metallic odor, often accompanied by discolored water.

Cracks, loose joints, or pervasive micro-leaks are allowing dangerous and unpleasant sewer gases to bypass their intended path to the vent stack and seep into living and working spaces.

Sometimes, the pipe system shows you the damage. Brownish-red stains on ceilings below bathrooms or around pipe penetrations are undeniable evidence of active seepage or condensation on chronically cold, sweating pipes.

In serious cases, you might see paint bubbling on pipes or feel how old cast iron is brittle and flaking, or notice galvanized steel with a rough, scaled surface. A pipe that looks corroded on the outside usually has even worse damage inside.

The material has reached the end of its service life. The electrochemical process of corrosion has eaten through the pipe wall, leading to failure.

Fixing plumbing issues with quick fixes like spot repairs, re-lining, or jetting is a classic case of temporary solutions. You're wasting money on a system that’s already outdated. Instead of trying to squeeze a few more years out of a failing setup, it’s better to install a new, durable system built to last the entire life of the building. This shifts the focus from just reacting to problems to investing in a long-term solution. Modern polymer plumbing systems, designed for durability and performance, make this proactive approach possible.

Quantum Industries’ Q-Therm piping systems are more than just products; they embody a complete building approach. Here’s how they effectively prevent the common failures seen in older metal piping systems.

Q-Therm pipes are made from a type of plastic called Polypropylene Random Copolymer (PP-R). They are naturally resistant to rust, scale, and corrosion, no matter what kind of water runs through them. The inside of the pipes is very smooth, with a surface roughness of just 0.007 mm, which helps keep water flowing freely for many years. This smoothness also prevents the buildup that can cause slow drains and clogs. These features are backed by international standards like ISO 15874, which ensure PP-R pipes are safe and reliable for drinking water.

Unlike metal pipes, which amplify every hydraulic shock and water movement, Q-Therm PP-R naturally dampens sound. Its flexible material absorbs vibrations and noise, preventing them from traveling through the building. This makes multi-story residential or office buildings much quieter and more comfortable, effectively stopping the so-called 'Phantom Orchestra.'

The main weakness in threaded or gasketed systems lies in their joints. Q-Therm solves this by using thermal fusion welding: the pipe and fitting are heated and joined directly, creating a seamless, single piece of plastic. This joint is actually stronger than the pipe itself and guarantees a leak-proof connection, fixing the common leak issues found in traditional systems.

Quantum Industries is chosen by many as the best among acoustic drainage system manufacturers and Suppliers in the UAE. This is due to the Q-Therm products from Quantum Industries that can last over 50 years for hot and cold water needs, making it a one-time investment. It helps you avoid ongoing costs like chemical drain cleaners, jetting services, emergency leaks, and early system replacements. Plus, PP-R is fully recyclable, and making and installing it is more eco-friendly than using metal pipes.

Recognizing the signs early is important. Acting wisely and promptly is the next step. Ignoring these issues can lead to costly emergency repairs, water damage, tenant turnover, and damage to your reputation, all of which often cost more than investing in a modern, reliable system.

An expert team of piping specialists can evaluate your building’s unique challenges and provide a clear, no-obligation assessment. This comparison shows how ongoing maintenance can become repetitive and costly, compared with the long-term benefits of a Q-Therm piping solutions.